Membrane Plate Filter Press Manufacturer NMP

페이지 정보

본문

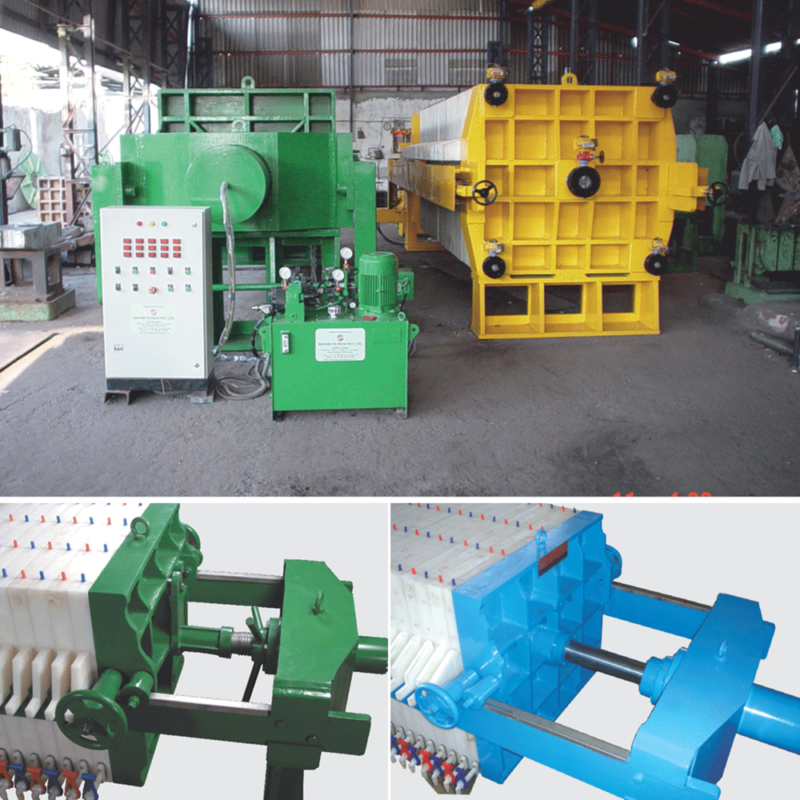

The unique idea for filter press were the Filter plate & frame, are still used in many industries.The filtration chambers of the filter presses with frames encompass two sorts of filter plates: body and filtrating. The thickness of the frame plate determines the thickness of the filtration cake - it often ranges between 10 - 50 mm. The versatility of course of gear extends throughout numerous purposes, together with pharmaceuticals, agriculture, environmental safety, and even area manufacturing. As technology continues to advance, the continued optimisation, automation, and analysis of these programs remain important for enhancing effectivity, ensuring safety, and contributing to the sustainable and managed evolution of industrial processes worldwide. Usually, the filtrate (liquid) exits the filter press plate and frame pack (plates) by way of nook ports right into a manifold. When the appropriate valves in the manifold are open, the filtrate moves out of the press by a single level, the filtrate outlet. The filtrate is then directed to the following part in the process by way of the discharge pipe. It is important to substitute any filter plate with harm to the Stay Bosses! 5. Plates may turn into cracked, warped, or broken and do should be changed occasionally. Whereas it is difficult to prescribe the exact variety of plates to keep as spares, we're happy to work with you on an optimal spare parts program on your filter press operation.

This enables the dewatered cakes to discharge extra easily than with traditional plate and frame presses. As a result of variability in slurry materials percent solids, particle size distribution, particle shape and materials makeup, each site’s materials ought to be examined prior to sizing a Filter Press for a specific customer application. The recessed filter plates are the successor of Filter plate and frames. There are 2 fundamental configuration of Recessed filter plates: Open Discharge & Shut Discharge. In both the configuration the chamber depth is definitive. Within the Open Configuration plates, filtrate discharges to be both a adaptable Bib or spigot on one facet or both the facet of the plates. In the sort of design the discharged filtrate could be visible from every plate and can identify torn filter cloth or other retention drawback.

The belt press uses two repeatedly transferring filter belts that are pushed and directed by 15-20 rollers. The rollers and roller bearings are exposed to the positive slurry particles as well because the filtrate that drains through the belts. This causes continual buildup of solids on the rollers and belts, which causes abrasion as well as overall corrosion, eventually requiring substitute of the rollers and belts. Your entire belt press should be cleaned periodically to prevent extreme buildup harm and to minimize abrasion and corrosion. Vacuum Membrane Plates, shown right here in the filter press, are effectively-suited to supporting the customer’s objective of achieving extraordinarily dry cakes (e.g. a cake moisture content material of 2% or less). Micronics affords a full range of filter plates including recessed, membrane, vacuum membrane and plate & body plates. Micronics specialists will enable you with the suitable cloth/plate combination on your unique utility and working conditions. Micronics provides you a complete range of filter plate sorts - each commonplace, inventory plates and particular, customized designs - and the experience to help you choose what is true on your system.

- 이전글Enhance Your Deepseek Ai With The following tips 25.03.07

- 다음글How To Lose Money With Restaurant Remodel Contractor. 25.03.07

댓글목록

등록된 댓글이 없습니다.