PLATE AND Body FILTER PRESS VS. RECESSED CHAMBER FILTER PRESS

페이지 정보

본문

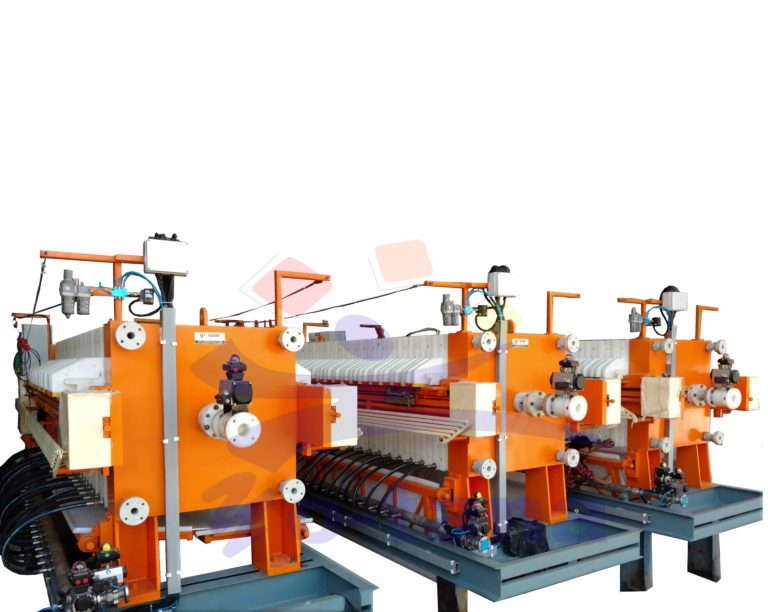

The filtration course of can continue until the press is full and no extra liquid may be pumped into it. 5. Unloading the filter cake: As soon as the filtration process is full, the hydraulic cylinder is used to open the press, and the filter cake is faraway from the press. The filter cake could be discharged by gravity or by mechanical means, akin to a scraper or conveyor. 6. Cleansing: Once the filter cake is eliminated, the press is cleaned by washing the filter cloths and plates with water or a cleansing answer. The press can then be reassembled and used for another filtration cycle. Pleasant working setting: the noise generated by the recessed plate filter press in the technique of operation is low, and the wastewater and waste residue discharged can meet the environmental requirements after remedy, consistent with fashionable environmental requirements. Mining: In the field of mining, recessed plate oil filter manufacturing machine presses are commonly used to extract useful elements from steel ores, comparable to extracting stable particles from steel ores reminiscent of gold, silver, and copper, and separating them from water. The stable particles within the slurry are separated from the water by the filter press, thus realizing the concentration and purification of the ore.

Membranes have a a lot shorter life than recessed filter plates because of the flexing required of the membrane each cycle below excessive pressures. The life of the membrane will rely on the variety of cycles carried out and supplies used. Some membrane plates can be found with replaceable membranes. Others require replacement of the entire filter plate when the membrane must be replaced. Combine Pack Membrane are the most common configuration (one recessed plate then one membrane plate alternate in the press plate pack). Membrane Plates normally operate at a squeeze pressure up to 17 bar. Special plates can be designed for larger feed & squeeze strain. Replaceable membranes can be changed easily.

Recessed filter plate can also be named chamber plates. It is widely used for filtration processes with regular dry strong filtration demands. It is accessible in both gasket and non-gasket model, with 4 sorts of feeding position: high, middle, corner and outdoors. Filter plate with gasket allows less likelihood of leakage than non-gasket kind of filter plate resulting from an o-ring seal around the chamber and the filtrate ports. Within the recessed filter press, the pressure is consistently growing over a time frame because the cake measurement is increased as a result of continuous operation of the filter press.

We can analyze your water from a chemical perspective to seek out the appropriate flocculants, coagulants, and pH balancers that we will used to treat your water earlier than it goes through mechanical separation. This helps to optimize the performance of your clarifiers and filter presses, giving you a greater and extra efficient complete water remedy.

- 이전글أعمال المدرب الشخصي: بناء أعمال مدرب شخصي ناجحة: الاستراتيجيات الأساسية لرواد الأعمال - FasterCapital 25.03.07

- 다음글Why You Should Concentrate On Enhancing Reputable Counterfeit Money Providers 25.03.07

댓글목록

등록된 댓글이 없습니다.